AUTOMATED

PROCESS RELIABLE

FLEXIBLE

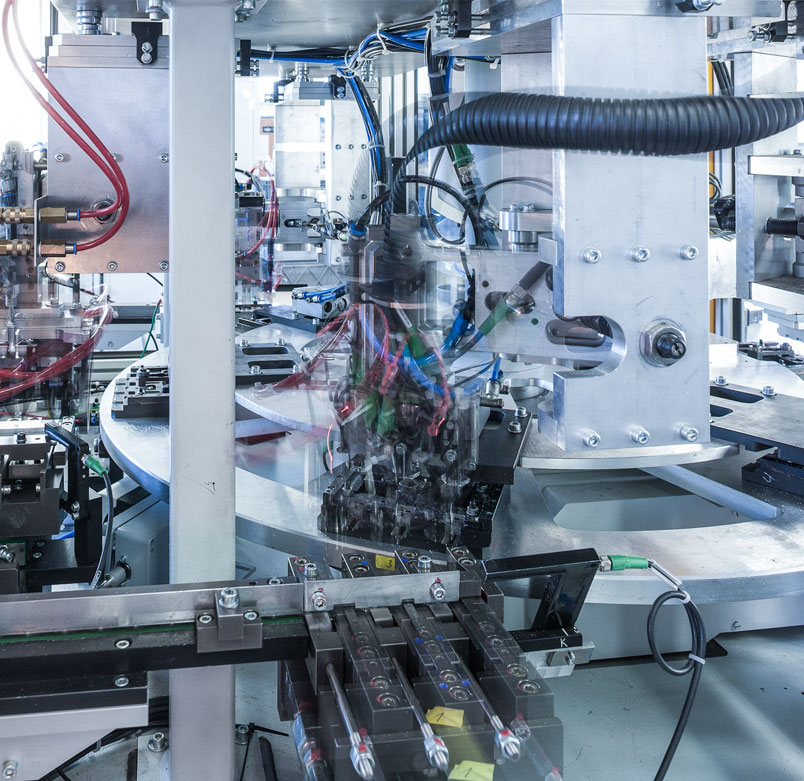

Flexible, precise and reliable

Ultrasonic welding, 2-component injection moulding, overmoulding of inserts, bonding and clipping are established assembly processes in our production. Especially in ultrasonic welding, you can rely on our wealth of experience when it comes to a precise and process-reliable weld seam.

Depending on the batch size, we work with fully automatic assembly machines and automated packaging or with semi-automatic machines. All assembly systems and workstations are integrated into our modern MES system.

We train our employees on each product and provide clear and understandable assembly documentation. As in the injection moulding process, quality inspections are documented automatically and manually in our CAQ system and the quality characteristics are evaluated using statistical methods with the aim of achieving zero-defect production.

ASSEMBLY AND ULTRASONIC WELDING