MODERN

RESOURCE-SAVING

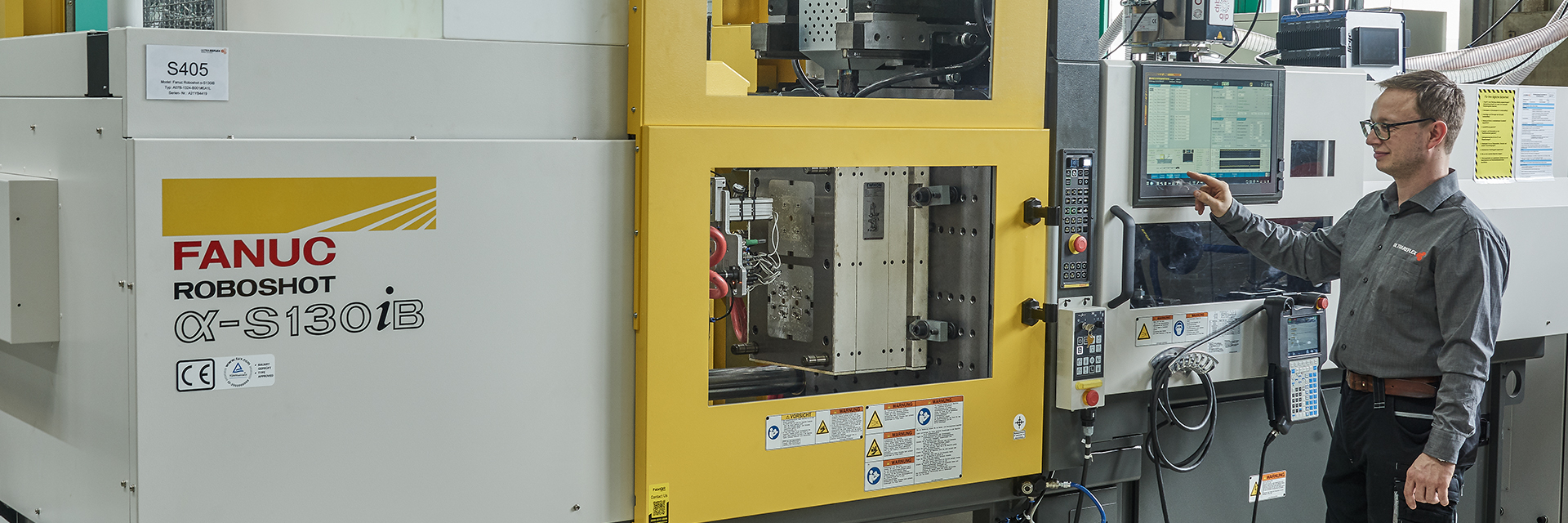

FULLY ELECTRIC

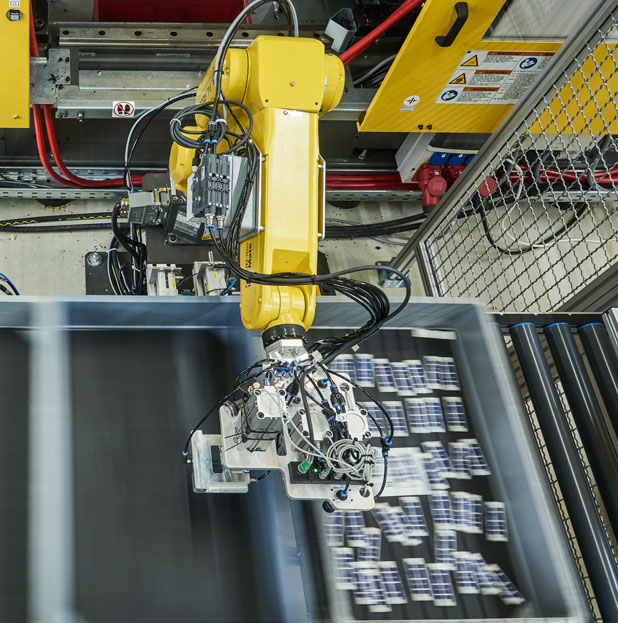

Automated, sustainable and precise

Our focus is on the processing of PMMA, PC, COP, COC and other transparent plastics. With 2-component injection moulding and injection compression moulding, we provide you with solutions to produce even more economical and precise parts for you in the micrometre range.

The manufacturing process is largely automated, digitalised and monitored from the central material preparation (central material conveying and drying system) to the finished packaged product. Every order is planned and controlled with our ERP and MES system. Quality inspections are documented in our CAQ system, partly automatically also. The test results are evaluated using statistical methods. Zero-defect production is always the basis of our evaluations and our goal.

Our injection moulding production is organised in such a way that we can react flexibly, quickly and on schedule to your needs. We are happy to prove that to you.

INJECTION MOULDING.