INNOVATIVE

COST-OPTIMISED

HIGH-PRECISION

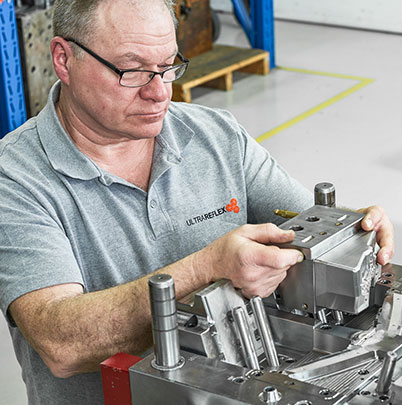

Efficient and very precise

We take care of the safe storage and consistent digitally supported maintenance and servicing of the injection moulds. This ensures the longevity of the moulds and optimum availability. We develop innovative and sophisticated tool concepts for you, such as 2-component injection moulds and injection-compression moulds. We manufacture prototype tools, interchangeable inserts or complete injection moulds. This means that the tailor-made solution for your project is available to you at all times.

With our knowledge, we support your product development in the optimisation of components, with the aim of ensuring cost-optimised, risk-minimised processes

The injection moulding tools we use are process-safe in production and thus ensure a smooth and safe production process.

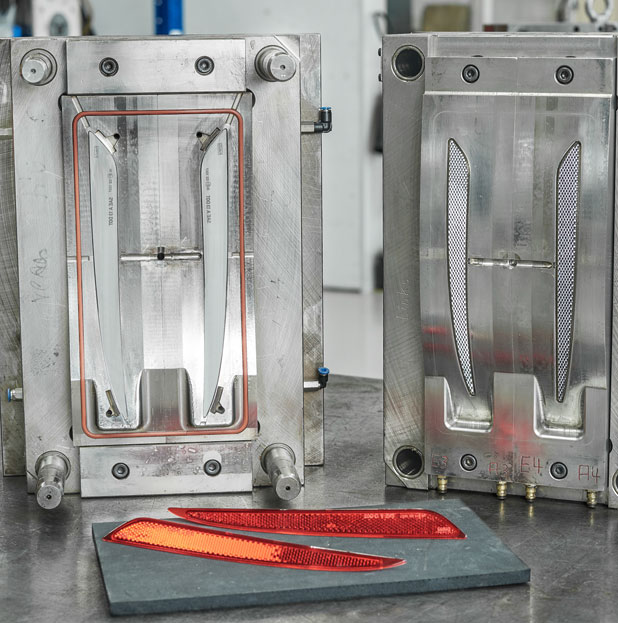

Our mould shop has many years of experience in the production of optical structures, microstructures and optics for reflectors and reflex reflectors with different prism systems. Take advantage of this competence.

MOULD MAKING